Industry News

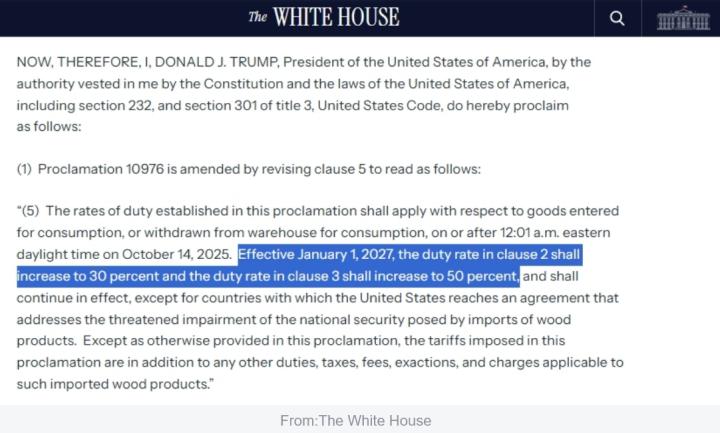

U.S. President Donald Trump signed a proclamation on December 31, 2025, postponing the implementation of planned tariff increases on imported goods such as upholstered furniture and kitchen cabinets for one year.

This means the current 25% tariff rate on these goods will remain unchanged. The previously scheduled higher rates—50% for kitchen and bathroom cabinets and 30% for upholstered furniture—originally set to take effect on January 1, 2026, are now postponed to January 1, 2027. While this deferral offers a valuable adjustment window for supply chains, the comprehensive cost and logistical challenges facing cross-border enterprises have not diminished.

Tariffs Deferred, but Cost Pressures Persist

This adjustment involves key categories, such as kitchen cabinets, whose tariff rate was originally slated to double from 25% to 50%. Despite gaining a temporary respite, the unpredictability of U.S. trade policy has become the new normal. Businesses must still prepare for potential future cost increases.

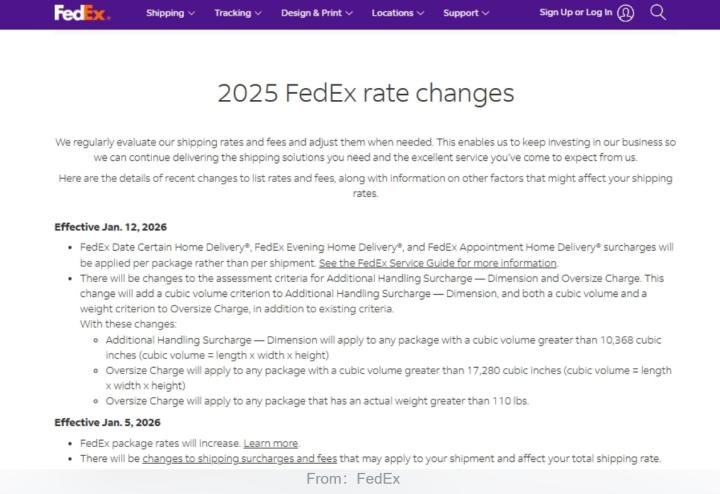

Meanwhile, international logistics costs are rising. For example, FedEx has announced adjustments to its global shipping rates and surcharges, effective January 5, 2026. Under the dual pressures of tariffs and logistics costs, controlling logistics expenses has become crucial for businesses.

Building a Robust Logistics Moat Through Comparative Analysis

Facing this dual squeeze, cross-border furniture companies urgently need to reassess their shipping plans, inventory strategies, and supply chain layouts based on product volume and value, transforming challenges into opportunities for supply chain optimization. This one-year buffer period is critical for stabilizing the entire logistics chain and preventing supply chain disruptions due to policy changes.

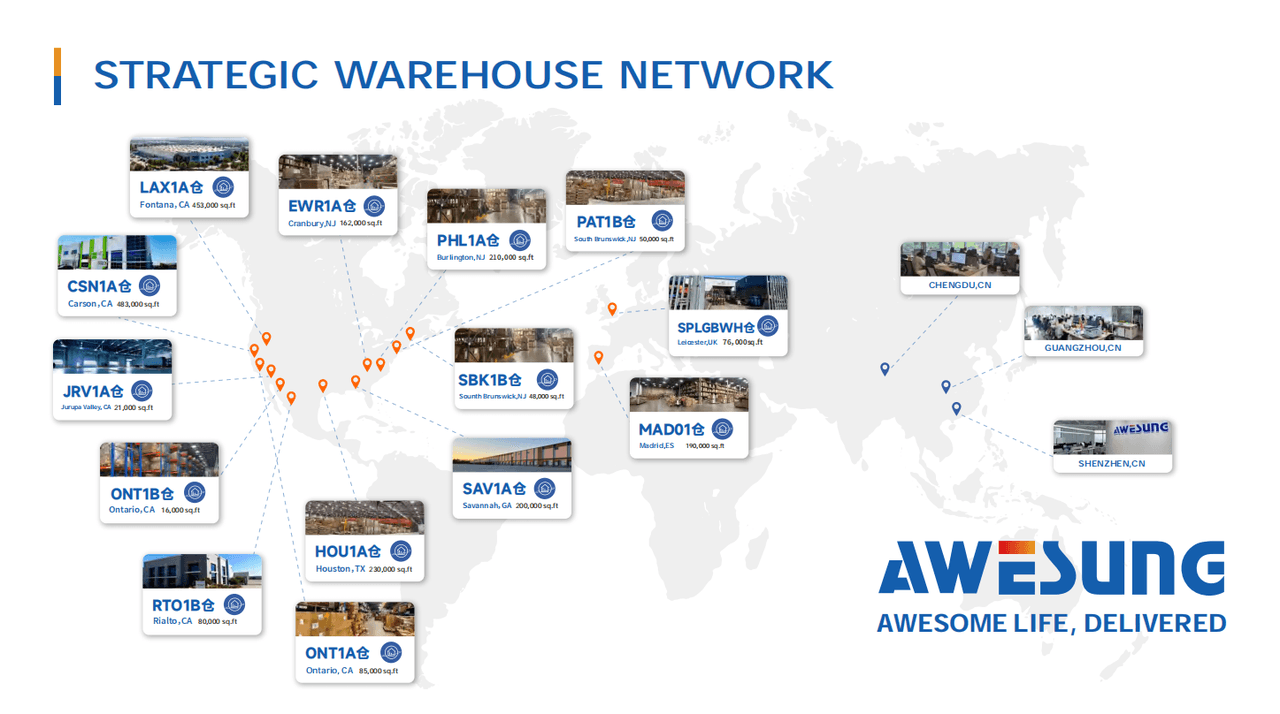

Deploying Overseas Warehouses to Mitigate Future Tariff and Logistics Volatility Risks:

By pre-positioning inventory to overseas warehouses located in the destination country, companies can not only significantly shorten last-mile delivery time to enhance customer experience but also effectively hedge against the direct cost impact of potential future tariff hikes.

When selecting service providers, key evaluation criteria should include their warehouse scale, operational stability, and system digitalization level in target markets (e.g., the U.S. and Europe). For instance, AWESUNG has established overseas warehouses across four major U.S. ports, totaling over 2.5 million square feet. Utilizing a self-developed system that supports seamless integration with multiple sales platforms, it ensures high inventory accuracy and timely shipment dispatch, providing businesses with reliable fulfillment guarantees.

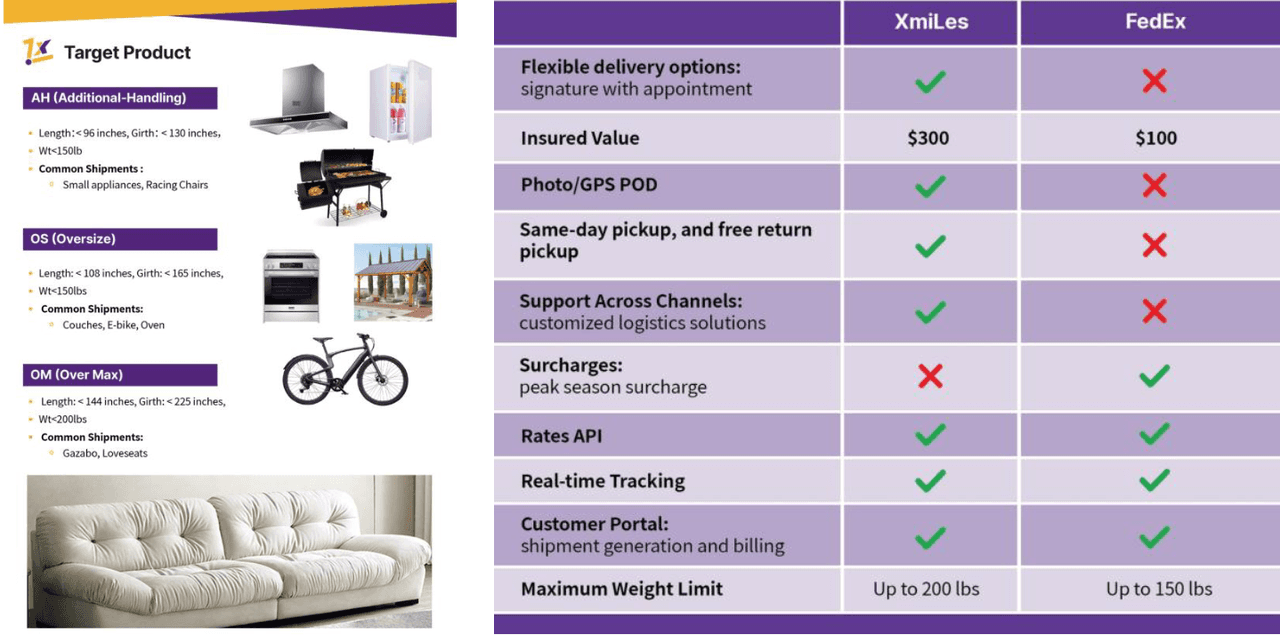

Selecting Tailored Last-Mile Solutions for Large Items to Control Logistics Costs:

Furniture products are typically large and heavy, placing high demands on last-mile delivery services. Choosing stable last-mile partners can help companies secure more competitive long-term shipping costs while ensuring service quality, thereby avoiding over-reliance on a single carrier and its price fluctuations.

In response to periodic rate increases from commercial carriers like FedEx, businesses need to compare last-mile solutions offered by different logistics providers. For example, XLmiles, a specialist in large and oversized parcel delivery within the United States, offers declared value protection up to $300, significantly higher than typical market offerings. It also provides more flexible size limits than FedEx, door-to-door service, transparent and stable flat rates, and a "50% off on second item" discount. This provides substantial support for large-item companies in reducing last-mile costs and improving efficiency.

This tariff postponement is a buffer, a challenge, and also an opportunity. It serves as a warning that the trade environment is fraught with variables, while also giving businesses nearly a year to forge a more resilient and efficient supply chain. In an era of uncertainty, transforming logistics costs into a competitive advantage and building a risk-resistant logistics system by choosing stable and reliable service providers is a long-term strategy to ensure steady business growth for cross-border furniture companies.